What does a floor tiles making machine line production include? The role of each?

News 2022年8月11日 133

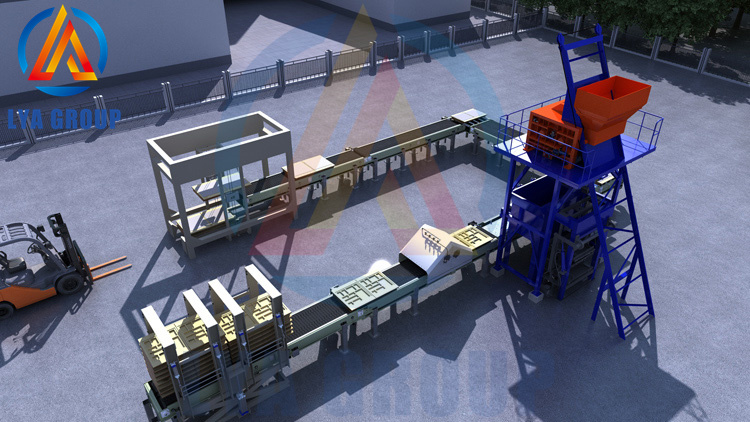

In order to save labor as much as possible and reduce the workload of workers, The precast concrete production line making machine is divided into 15 parts from ingredients to packaging, which are connected and operated through a programmable control cabinet, each part and half part can work independently.

All the parts include cement silo, batching machine,Auto Concrete forced Mixer,auto unloading machine , auto pallet turning machine,Auto Spray Machine,concrete filling machine,auto stacking machine,auto packing machine,auto demoulding machine,auto vibration part,Hydraulic conveyor,Air compressor,auto screen controller ,dust collecting machine.

Let’s learn the function of each part of paving block artificial stone production line:The cement silo, used to stock the cement in the tank and ship the cement powder to the batching machine as required quantity. As for artificial stone producing capacity, the 30T model is the suitable one.

The cement silo tank is equipped with a material level system, which can display the position and amount of the material, and the hole-breaking device can relieve the solidity caused by the material deposition for too long.

At present, the more common types of cement silos on the market include horizontal cement silos, vertical cement silos, and assembled cement silos (also called sliced cement silos).

1. The horizontal cement silo is square, the bottom is supported by several legs, the discharge cone is a square cone, the silo is welded by a frame composed of corrugated cardboard and profiles, and the overall height is low.

The production workshop of the horizontal cement silo is a complete set of production, and there is no basic installation on site. The horizontal cement silo is mainly used for mobile batching plants and concrete batching plants.

2. The vertical cement silo is a cylindrical structure, and the bottom is supported by four round tube legs. The entire silo is welded with steel structure, and the top is equipped with a dust collector and a pressure relief valve.

Vertical cement silo is suitable for bulk cement and dry fly ash. It has the characteristics of rainproof, moistureproof and easy to use. Usually used as a supporting product for concrete batching plants (construction).

3. Prefabricated cement silo, also known as sheet cement silo, is made into thin sheets during production, which is convenient for transportation and used after assembly, especially suitable for export.

The installation of the flake cement silo is more complicated and the cost is higher, but the transportation of the flake cement silo is more convenient.