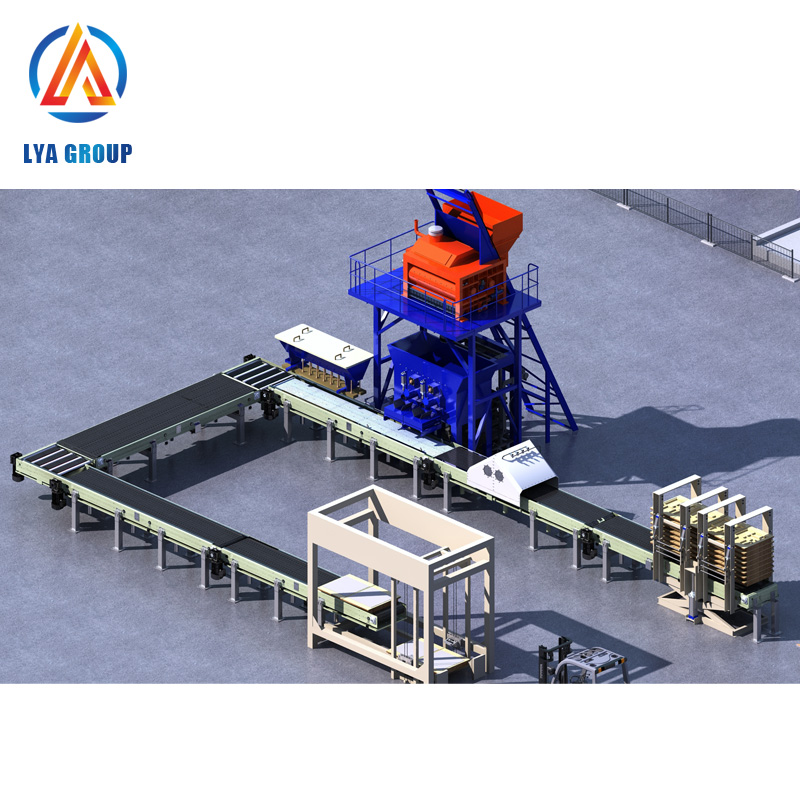

Batching machine of the floor tiles making machine line production

News 2023年2月21日 93

In order to save labor as much as possible and reduce the workload of workers, The precast concrete production line making machine is divided into 15 parts from ingredients to packaging, which are connected and operated through a programmable control cabinet, each part and half part can work independently.

All the parts include cement silo, batching machine,Auto Concrete forced Mixer,auto unloading machine , auto pallet turning machine,Auto Spray Machine,concrete filling machine,auto stacking machine,auto packing machine,auto demoulding machine,auto vibration part,Hydraulic conveyor,Air compressor,auto screen controller ,dust collecting machine.

Let’s learn the function of batching machine of paving block artificial stone production line:

Three warehouse batching machine is a new type of electronic batching machinery, suitable for general construction sites, roads, bridges and other projects. This batching machine can be used for batching concrete mixers with a discharge capacity of 1000 liters and below. The material can be picked up by the belt conveyor. The weighing system of the electronic batching machine adopts the weight controller and sensor, which can quantify, batch and control the material, and automatically modify the drop. The electronic batching machine has the advantages of reasonable layout, compact structure, simple operation, accurate batching and reliable control.

When the batching starts, the belt conveyor starts to bring out the raw materials in the storage hopper to the set value, and the belt stops. Then, under the control instrument, the materials are arranged in turn, until all the materials are configured, the instrument control will start the unloading belt to send the materials into next session.

1. Automatically complete the batching measurement of 2-4 kinds of materials such as sand, stone and cement;

2. Microcomputer control, automatic and manual functions are complete, and the anti-interference ability is strong;

3. It can be combined with various types of thinner gauges to form an assembled mixing station;

4. Easy installation and debugging, few wearing parts, strong adaptability;

5. The form of supporting combination is diverse and flexible