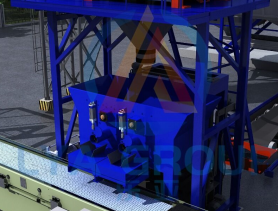

Auto Wet Conrete Dosing System Production line

News 2023年3月11日 76

Wet concrete dosing system is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for wall and floor paving, 3D Wall panel, terrazzo floor tile, etc .

Auto Wet Conrete Dosing System Production line include :Wet concrete dosing system , Cement Silo ,Batching machine, Auto Concrete forced Mixer,Forklift,Auto unloading machine,Auto Spray Machine,Auto Dosing Machine,Auto Stacking Machine,Pallet transfer machine,Empty Pallet Belt conveyor,Full Pallet Belt Conveyor,Air compressor,Auto Screen controller .

Auto Dosing Machine:It include the mixing hopper, concrete doser with pneumatic control and storage silo;

Auto Dosing Machine the bright spot :

1.concrete dosing can be calculated kilograms, not by time; thus to keep the dosing in a more accurate way.

2.Pneumatic door switching design, not wasting any more concrete for each dosing.

3.Adopt the storage silo for saving the concrete from each dosing, can save up to 75kg each time.

4.It has vibration function assembled with the dosing part, after dosing the concrete on the molds then will start vibration .

5.Digital screen controller, with all dosing weight available by only setting up the button ,it is fully automatic mode.

6.Save 6-8 labors for the factory, and reduce the working strength of the labors.

7.Adopt the frequency motor, all size of raw material will not stuck at the mixing & dosing process. make sure machine parts will long lasting use and power saving.

Kevin