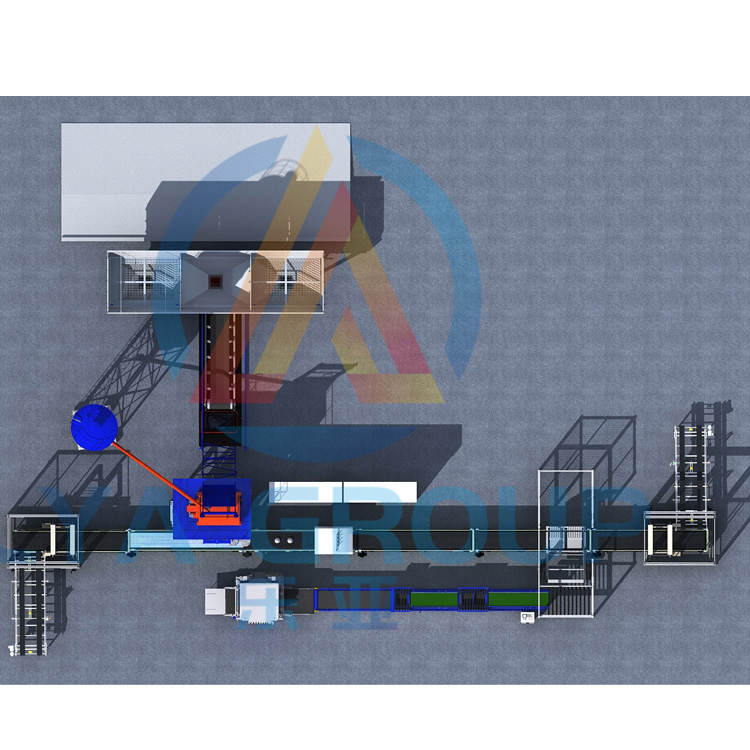

Standard Paving Block Production Line

News 2023年4月11日 106

Standard paving block production line, is suitable for different silicone artificial stone molds and plastic and rubber paver molds, size range from 200*200mm to 1500*1500mm, available for producing the wooden paving stone both for wall and floor paving, 3D Wall panel,Mushroom stone, terrazzo floor tile, etc .

So what materials and equipment are required for the completion of this standard production line?

- First of all, raw materials are essential:42.5# cement、washed sand、 5-10mmGravel、Iron oxide pigment、concrete hardener & brightening agent.

- 2 vibrate tables: for vibrate the air bubble in the concrete cement to improve the strength of the interlock pavers and artificial stone etc, and this vibration table can move the molds forward automatically.

- 2 mixers: First color layer mixing: Mix the cement、gravel、washed sand、iron oxide color and others well. Second concrete layer mixing:Mix the gravel、washed sand、cement、concrete hardener again.

- Demoulding machine: To release the molds from the concrete paver mold,normally 4-5 times higher than the efficiency by hand. No more damage on the plastic molds itself.

- Heating table: It is used to heat the room temperature, maintain room temperature balance, and accelerate demoulding.

In addition to these main equipment, customers also need to prepare crushers, etc.; also need to make a small sample room to meet the needs of making samples.

If you want to know more about the production of floor tiles, you can contact us.