What equipment is included in the tile production line?

News 2023年6月29日 80

With the rapid development of society, manual labor is gradually being replaced by machines. Mechanical automation is the direction of industry development. Production lines save labor, improve work efficiency and output, and provide corresponding production lines for people who do not need them. Now, let’s talk about the most basic manual tile production line. The principle of manual tile production line is convenience, speed, and easy operation. So what devices does it include:

Mixer: Mixing concrete to mix various raw materials together.

The manual tile production line generally uses JB250 and JB350 flat end mixers, with a power of 4-5.5KW, a voltage of 380-440V (customizable according to the customer’s local voltage), a frequency of 50/60Hz, and 3Phases.

The commonly used manual mixer is usually the LYA-HM-200 model, with a power of 2.5KW, a voltage of 380-440V (customizable according to the customer’s local voltage), a frequency of 50/60Hz, and 3Phases.

Vibration platform: Shake out the bubbles in the concrete and flatten the surface, making the concrete fit the mold more closely and the patterns clearer.

LYMP-2000 and LYMP-3000 vibration platforms commonly used in manual tile production lines, power: 1.1-2.2KW, voltage: 380-440V (customizable according to the customer’s local voltage), frequency: 50/60Hz, 3Phases.

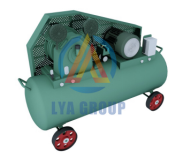

Air compressor+spray gun: Clean mold dust and spray mold release oil.

The commonly used air compressor model for manual tile production line is LYA-S-02, with a power of 7.5KW, voltage of 220V/380-440V (customizable according to the customer’s local voltage), frequency of 50/60Hz, 3Phases.

Spray gun model LYA-S-01, capacity: 1000mL, caliber: 2mm, air pressure: 0.3~0.7Mpa.

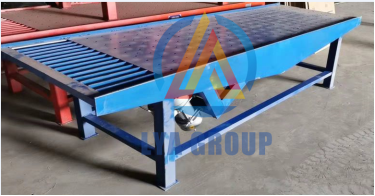

Floor tile demolding machine: separates the produced bricks from the mold.

The commonly used demolding machine for manual tile production lines is the model LYA-D-02 with track conveyor, with a power of 1.3KW, a voltage of 380-440V (customizable according to the customer’s local voltage), a frequency of 50/60Hz, and 3Phases.

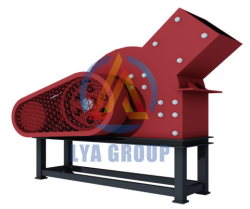

Floor tile crusher: Recycling damaged floor tiles for reuse.

The commonly used crusher model for manual tile production lines is LYPC-300, with a power of 7.5/8KW, voltage of 380-440V (customizable according to the customer’s local voltage), frequency of 50/60Hz, 3Phases.

Special brick cutting machine for floor tiles: Cut the tiles into the specified shape to achieve the installation effect.

The commonly used brick cutting machine model for manual tile production line: LYBC-1000, cutting size: width: 400mm, thickness: 10-100mm

Cement product oven: Faster and higher quality drying of concrete products to save more electricity and labor costs on the production line.

The commonly used oven model for manual tile production lines is HJ101-3, with a power of 6KW, a voltage of 380-440V (customizable according to the customer’s local voltage), and a frequency of 50/60Hz.

Theoretical knowledge needs to be combined with practice, and machines require practical operation to understand more thoroughly. Therefore, if you would like to learn more information, please feel free to contact us and visit our factory.