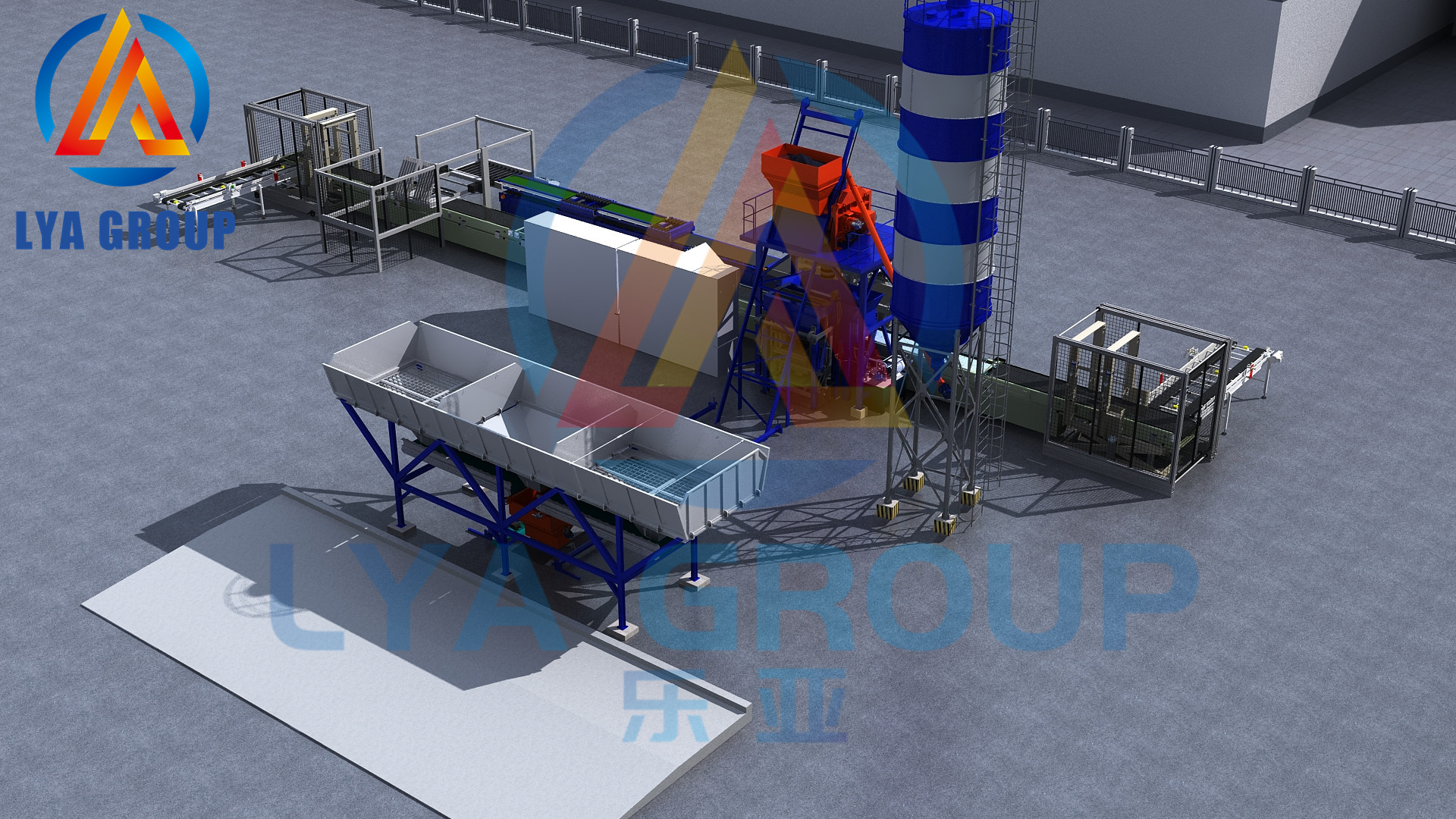

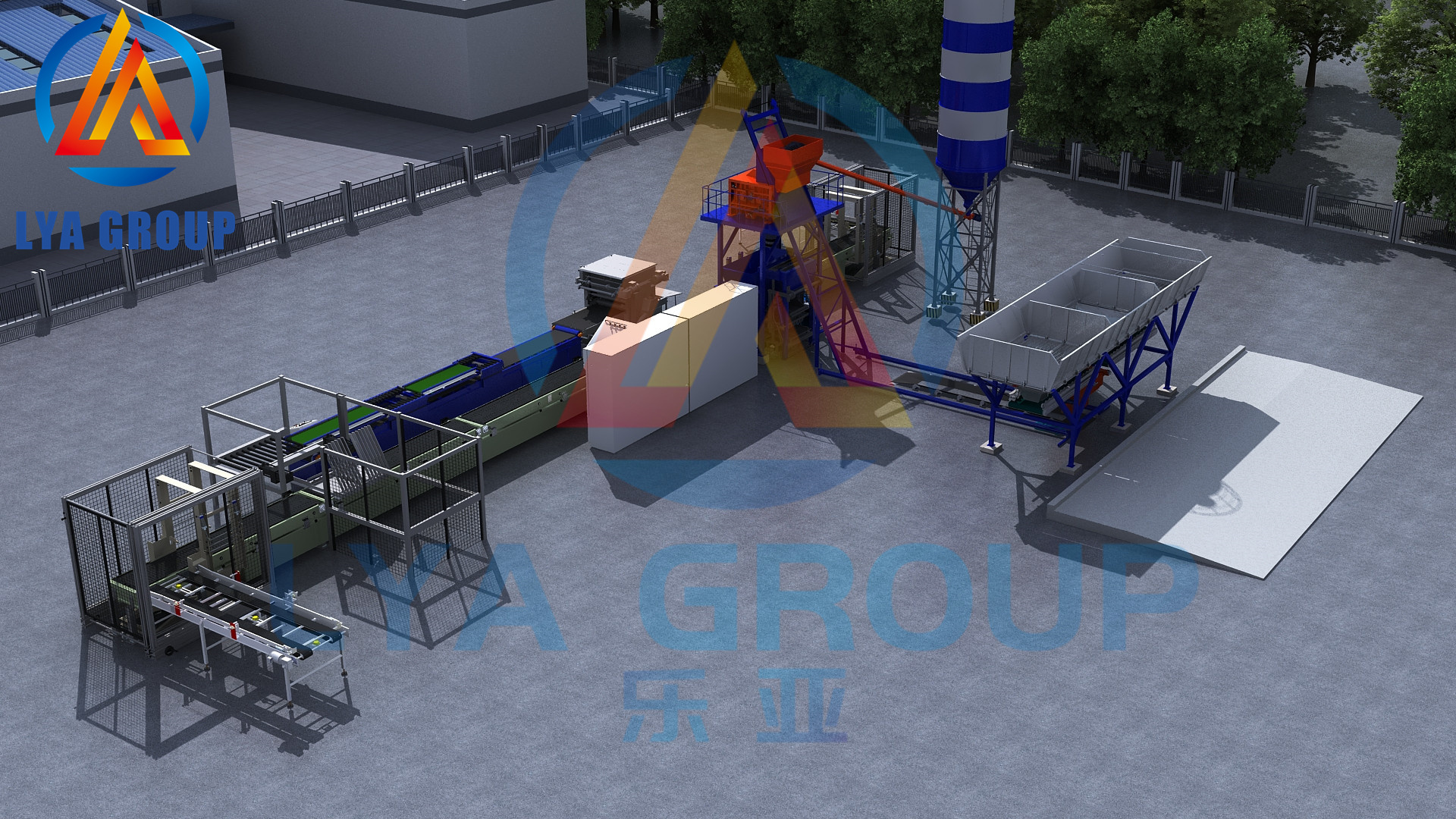

Factory manufacture fully automatic kerb stone manufacturing machine wet cast concrete

Enquiry Email: harvey_lya@zzlya.com

Product DescriptionWet cast concrete refers to a method of casting concrete that involves the use of a high water-to-cement ratio, resulting in a more fluid and workable concrete mix. This ……

Introduction

Product Description

Wet cast concrete refers to a method of casting concrete that involves the use of a high water-to-cement ratio, resulting in a more fluid and workable concrete mix. This method is commonly used in the production of various precast concrete products, such as architectural elements, paving stones, retaining walls, and other structural components.Wet cast concrete offers several advantages, including the ability to produce complex shapes, excellent surface finishes, and high strength. Additionally, wet cast concrete products can be manufactured with a wide range of colors, textures, and patterns to suit different architectural and design requirements.

The process of wet cast concrete typically involves the following steps:

- Mixing: The concrete ingredients, including cement, aggregates (such as sand and gravel), water, and additives, are mixed together in a concrete mixer. The water content is relatively high compared to other methods, resulting in a more fluid consistency.

- Mould Preparation: Moulds are prepared to shape the wet cast concrete into the desired product design. The moulds can be made of various materials, such as steel, rubber, or fiberglass, and are typically coated with a release agent to facilitate easy removal of the cured concrete.

- Pouring: The wet cast concrete mix is poured into the prepared moulds. The high water content allows the concrete to flow easily and fill the moulds, ensuring that complex shapes and intricate details are accurately reproduced.

- Compaction: To ensure proper compaction and consolidation of the wet cast concrete, vibration or other mechanical means are often employed. This helps remove air bubbles and ensures that the concrete fully fills the moulds, resulting in a dense and durable final product.

- Demoulding: Once the concrete has cured to the desired strength, the moulds are removed to reveal the finished wet cast concrete product. Careful demoulding is necessary to prevent any damage to the concrete.

| Name | Artificial stone production line | Artificial stone production line |

| Model | HTX-P-01 | HTX-P-01A |

| Specification | Hydraulic driving;Auto feeding;vibrating and timing feeding | Full Auto,timing feeding and vibration, weighing system; |

| Size(mm) | 7000*1000*1800 | 12000*1000*2000 |

| Power(Kw) | 12.7 | 9.1 |

| Capacity(m2/day) | 1000-1200 | 800-1000 |

| Weight(Kg) | 2000 | 1500 |